12Lf-xxPT-90 Datasheet

1. Features

- Micro size

- Precise position control

- Force control by current feedback

- Speed control (1024 resolution)

- Strong force comparing to the size

- Built-in Drive Circuitry

- TTL/PWM communication

- Parameter programmable on the Manager software

2. Specification

2.1 Common Specifications

| Property | Value |

|---|---|

| Stroke | 90mm |

| Rated Load | 10N ~ 78N |

| Recommended duty cycle at rated load | 50% |

| Max apllicable Load | 2times rated load |

| Recommended duty cycle at max applicable load | under 20% |

| Micro controller | 32bit Arm Cortex |

| Position Resolution | 4096 Resolution (A/D Converter) |

| Input Voltage | 12.0V(Rated), 7.4V ~ 13 V(Operating) |

| Motor Type / Watt | Coreless DC Motor / 3.5 Watt |

| Current consumption | 30mA(Idle), 380mA(Rated), 1.6A(Stall) |

| Position repeatability | Unidirectional less than 0.05mm(50um) |

| Bydirectional less than +/0.1mm(100um) | |

| Current Tolerance | ±15% at Over 50mA |

| Position sensor | 10kΩ linearity potentiometer |

| Size, Weight | 151.5(L)x36(W)x18(H)mm /177g (to be varied according to gear ratio) |

| Communication | TTL/PWM(Automatic signal recognition) → TTL Level voltage : 3.3 ~ 5.0V → PWM Pulse range : 900us(retracted) – 1500us(center) – 2100us(extended) → TTL Communication range : Max.4m |

| Protocol | IR Robot Open Protocol (switchable to MODBUS RTU protocol) |

| Operating Temperatures | -10℃ ~ 60℃ |

| Ingress protection | IP-54 |

| Mechanical Backlash | 0.03mm(30um) |

| Audible Noise | Max. 50db at 1m |

| Gear ratio | 10:1(10PT,17PT,27PT) /20:1(42PT) /30:1(55PT) /50:1(78PT) |

| Gear type | Engineering plastic gears(10PT,17PT,27PT) 4metal & 2engineering plastic gears(42PT,55PT,78PT) (Aluminum and stainless steel combination) |

| Rod type | Stainless steel rod |

| Standard Accessory | 1xHinge base 1x Hinge 1xHinge shaft 1xRod end tip 2x M3 NUT 3 x M2.5x6 screws 1x Molex wire harness (200mm) 1 x M3 spanner 1 x Socket set screwlex wire harness (200mm) 1 x M3 spanner 1 x Socket set screw |

| Connector Type (Male) in the Actuator | MOLEX 22-03-5035 |

| Wire Harness | Molex(50-37-5033) to Molex(50-37-5033)/ 200mm / 0.08x60(22AWG) |

2.2 Volatges

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| Supply voltage | 7.4 | 12 | 13 | V | |

| Logic input voltage | 2.0 | 3.3 | 5.5 | V | TTL |

2.3 Currents

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| Maximum peak Current | ≤1.6 | A | Stall Current | ||

| No Load Current | ≤300 | mA | No Load | ||

| Rated Load Current | ≤400 | mA | |||

| Max Applicable Load Current | ≤600 | mA | |||

| Idle Current | ≤35 | mA |

2.4 Temperatures

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| StorageTemp. | -20 | - | 70 | ℃ | |

| Operating Temp. | -10 | - | 60 | ℃ |

2.5 Strokes

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| MIN Position | 5.3 | 5.8 | 6.3 | mm | ⁕ |

| MAX Position | 95.8 | 96.3 | 96.8 | mm | |

| Stroke length | 90.5 | mm |

- Contact us if min position of multiple actuators should be exactly same.

- Synchronize Min / Max Position by “Min / Max Position Calibration” feature on Manager software or Parameter Map

2.6 PWM

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| MIN Pulse | 900 | us | Period is 8ms over | ||

| Neutral Pulse | 1500 | us | |||

| MAX Pulse | 2100 | us |

2.7 No Load Speed

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| Maximum Speed at 12.0V | 104.4 | 116.0 | 127.6 | mm/s | 12Lf-10x-90 |

| 45.6 | 84.0 | 92.4 | mm/s | 12Lf-17x-90 | |

| 26.1 | 29.0 | 31.9 | mm/s | 12Lf-27x-90 |

2.8 Load

| Parameter | Min | Rated | Max | Unit | Note |

|---|---|---|---|---|---|

| Load at 12.0V | 10.0 | 20.0 | N | 12Lf-10x-90 | |

| 2.24 | 4.49 | lbf | |||

| 1.01 | 2.03 | kgf | |||

| 17 | 34 | N | 12Lf-17x-90 | ||

| 3.82 | 7.64 | lbf | |||

| 1.73 | 3.47 | kgf | |||

| 27 | 54 | N | 12Lf-27x-90 | ||

| 6.07 | 12.13 | lbf | |||

| 2.76 | 5.51 | kgf |

⁕ 1 kgf = 9.8N, 1lbf = 4.45N

Caution

Use under rated load conditions if possible. When applying max applicable load (2x rated load), set Goal current to 1600(1.6A) and reduce Duty cycle to 20% or less.

2.9 Self Lock Feature

| Parameter | Min | Norm | Max | Unit | Note |

|---|---|---|---|---|---|

| Slef Lock | - | N/A | - | 12Lf-10x-90 | |

| - | - | 12Lf-17x-90 | |||

| - | Available | - | 12Lf-27x-90 |

Tip

Self-Lock means the actuator can hold its position by mechanical friction without motor power.

3. Reference Data

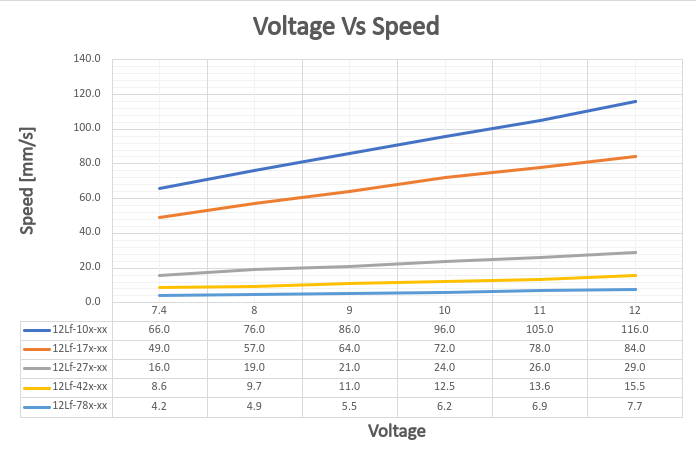

3.1 Voltage Vs Speed

Graph of speed change at no load according to input voltage. This data includes error and is for reference only.

Note

Voltage Vs Speed data was tested at Goal Current 800. This data includes about +/-15% error.

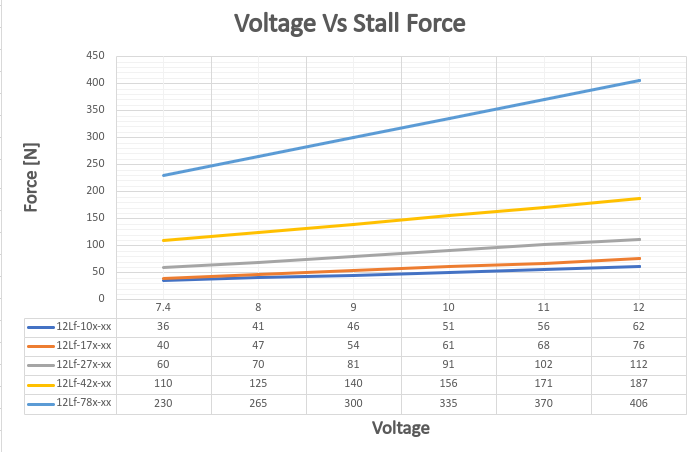

3.2 Voltage Vs Stall Force

Stall Force measured at 800mA according to input voltage. This data includes error and is for reference only.

Note

Voltage Vs Stall Force data was tested at Goal Current 1600. Each Force value has an error of +/- 15%.

Caution

Stall force is for reference only. To prevent product damage, use within rated load in actual applications.

3.3 Goal Speed Vs Speed

Shows no load speed change according to Goal Speed Parameter value at Goal Current 800. At less than rated load, the time to reach maximum speed varies depending on the load. ![goalspeedVSSpeed]00_goalspeedVSspeed.png)

Note

Goal Speed Vs Speed data was tested at Goal Current 800.

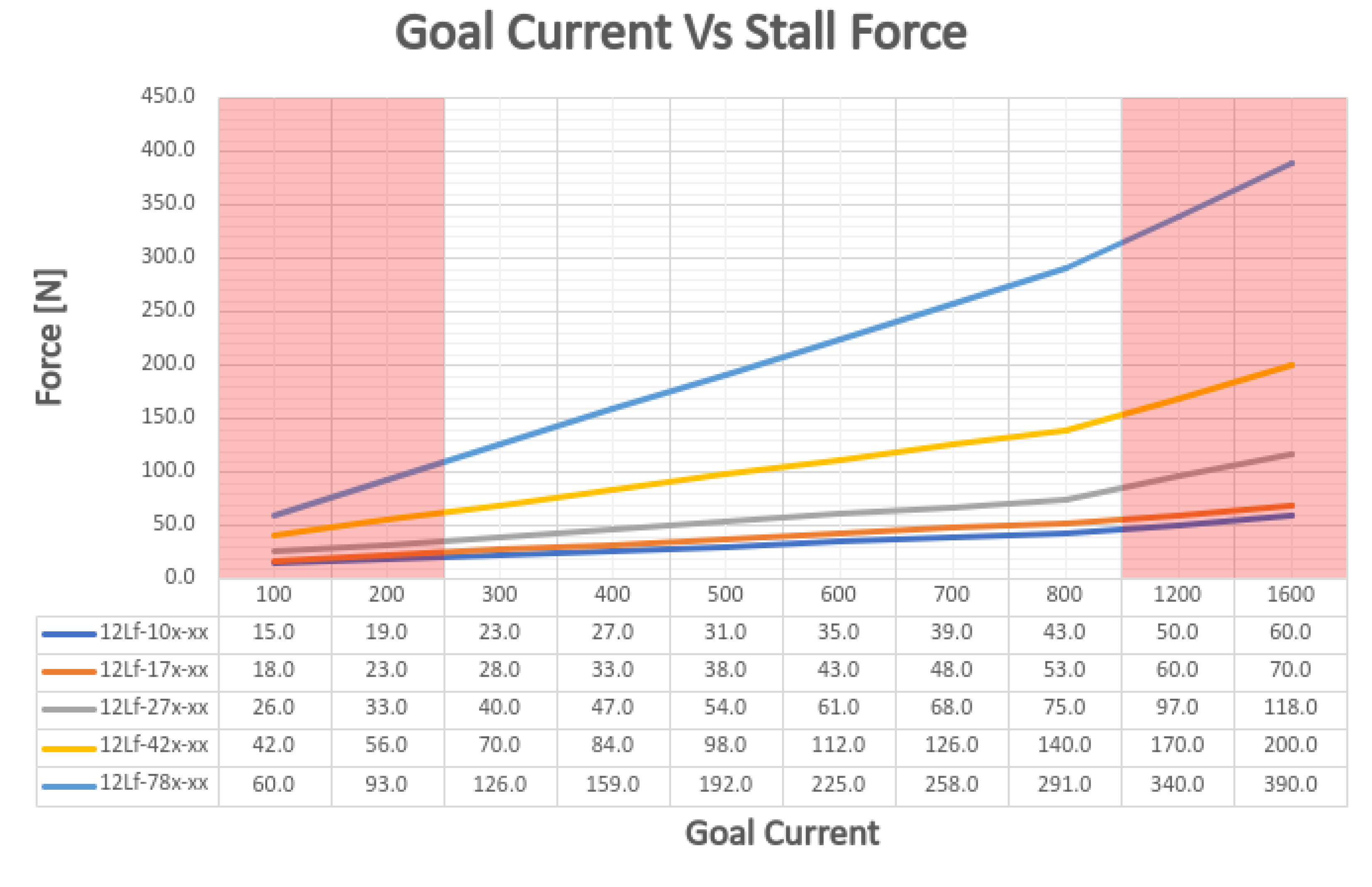

3.4 Goal Current vs Stall Force

Shows mightyZAP's Stall Force for each Goal Current value. Stall Force was measured at minimum speed to reflect only current-based force.

TIP

This data shows motor force. It is recommended to set Goal current to 3 times the actual load. If the difference between actual load and motor force is small, speed decreases. If equal, the motor does not move.

Caution

Each Stall Force value has an error of +/- 15%. Red-marked areas have large error due to internal load and heat, use for reference only. If continuous load causes current over 1A, current value will gradually drop and stabilize at 1A.

Double load setting

mightyZAP can be used up to double load. For double load, set Duty Rate to 20% or less. ex>

| Load | Goal Current | Duty rate | Load | Goal Current | Duty Rate |

|---|---|---|---|---|---|

| 20N(Rated) | 800 | Max. 50% | 35N(Rated) | 800 | Max. 50% |

| 40N(Max) | 1600 | Max. 20% | 70N(Max) | 1600 | Max. 20% |

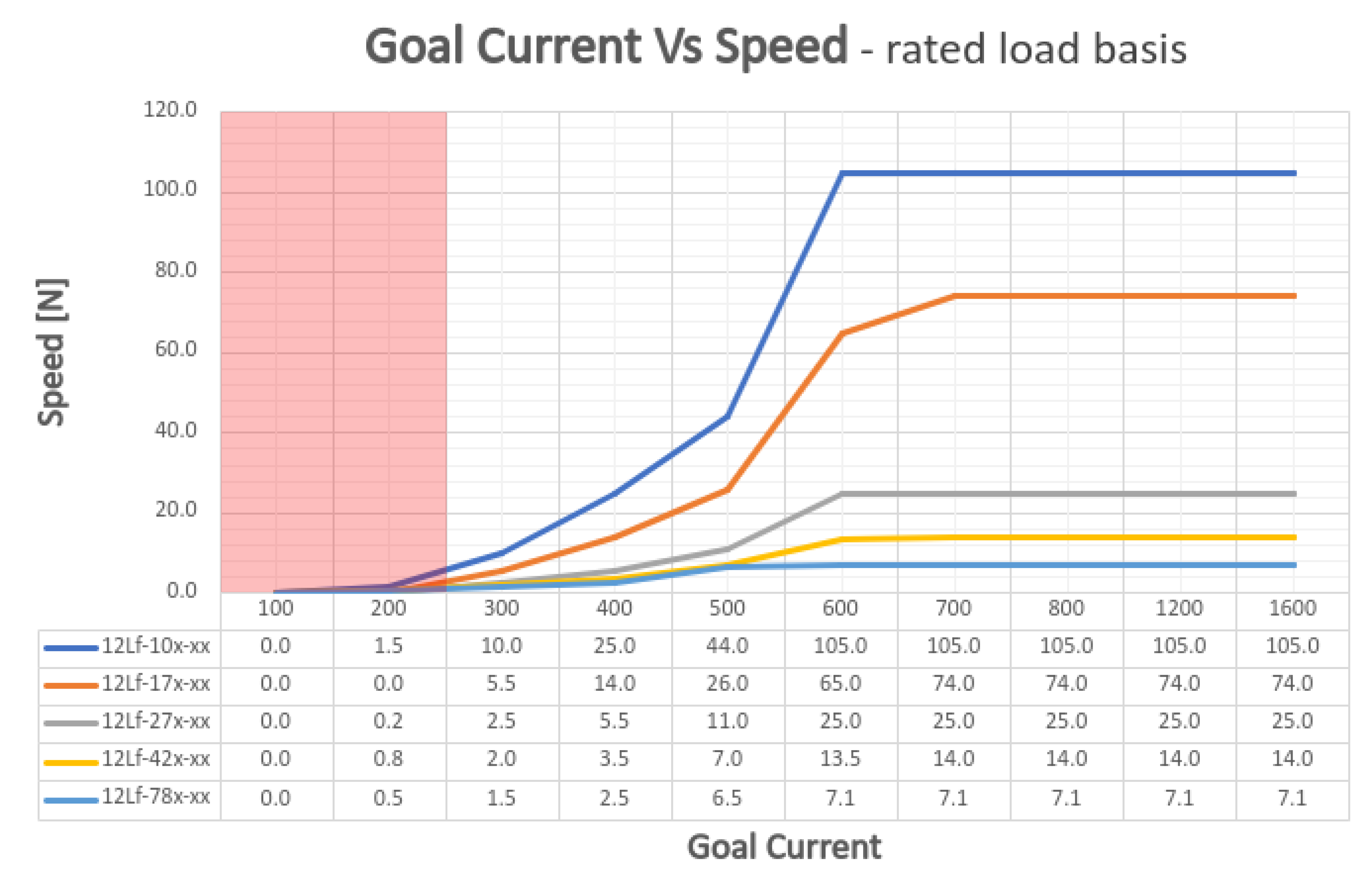

3.5 Goal Current vs Speed

Shows mightyZAP speed change for each Goal Current value at rated load.

TIP

Goal Current Vs Speed data was measured at rated load.

Caution

Speed data has about +/-10% error. Red-marked areas are where Stall Force and rated load are similar, so mightyZAP may not move. Use for reference only.

3.6 PIN Map

| PIN NUMBER(COLOR) | PIN NAME | FUNCTION |

|---|---|---|

| 1(WHITE) | DATA | Communication |

| 2(RED) | VCC | Power + |

| 3(BLACK) | GND | Power - |